Measuring the Effect of Temperature on LED Performance

Good thermal design of LED light sources and luminaires is essential to ensure optimum LED performance with respect to light output and lifetime. LEDs do not radiate significant amounts of heat but within the LED’s semiconductor junction heat is generated which must be dissipated by convection and conduction. The internal quantum efficiency of LEDs decreases as the junction temperature increases. Junction temperature increases as the current through it is increased. Therefore, the operating junction temperature is determined by the drive current, ambient temperature and the efficiency of the heatsink design.

Quality Control of LEDs

Lighting manufacturers ensure the quality of their products by measuring photometric and colorimetric parameters such as luminous flux, spectral power distribution, colour temperature and colour rendering.

This requires precise control of the drive current and temperature stabilisation of the test device during the measurement as detailed in CIE S 025/E:2015 [1]. Most LED lighting products are operated in either constant current mode (Continuous Wave, CW) or some form of PWM, pulse width modulated current mode (Quasi-CW). However, when specifying or ‘binning’ their products, LED chip manufacturers test their devices in single pulse mode. Therefore, test systems benefit greatly from allowing operation of the LED in both continuous wave and pulse mode, thereby permitting direct comparison of device performance with manufacturers’ claims, for example.

Furthermore, the latest standards recommend the use of the differential continuous pulse (DCP) method. This method is described in detail in standard IES LM-92-22 [2] as well as in the upcoming publication of CIE TC2-91[3]. This method uses two successive pulses in order to remove the LED’s short-term jitter on the microsecond scale and below. At the same time, heating effects of the LED can be avoided since pulse length is on the microsecond scale.

Optical Measurement Solution and LED Test System

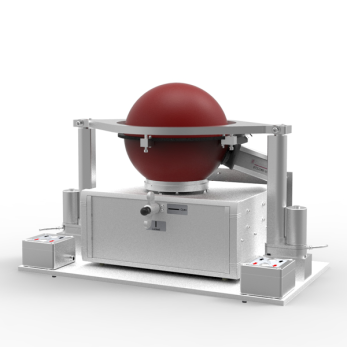

The TPI21-TH LED testing system provides fully automated testing routines for SMD and on-board LED devices. The system’s photometric, colorimetric, thermal and electrical measurement parameters all conform to the latest norms and regulations including CIE S 025, IES LM-79-24 [4], and DIN 5032 Part 9 [5].

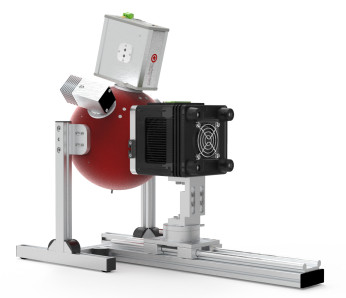

The DCP LED Test Station provides an IES LM-92-22 compatible LED testing setup that allows using either the differential continuous pulse method, the short or the long pulse method. The system also allows monitoring an LEDs long term thermal behavior by powering it continuously.

References

[1] CIE S 025/E:2015 Test Method for LED lamps, LED luminaires and LED Modules

[2] IES LM-92-22: Optical and Electrical Measurement of Ultraviolet LEDs

[3] CIE TC2-91

[4] IES LM-79-24 Electrical and Photometric Measurements of Solid-State Lighting Products